- Home Page

- Company Profile

-

Our Products

- Ceramic Fibre Products

- Refractory Castables

- Alumina Bricks

- Ceramic Fiber Blanket

- Fire Proof Cement

- Acid Proof Brick

- Acid Proof Cement

- Acid Proof Tile

- Insulating Castables

- Ceramic Fibre Board

- Ceramic Paper

- Conventional Castables

- High Alumina Brick

- High Alumina Cement

- High Alumina Mortar

- Low Cement Castable

- Porosint Bricks

- Contact Us

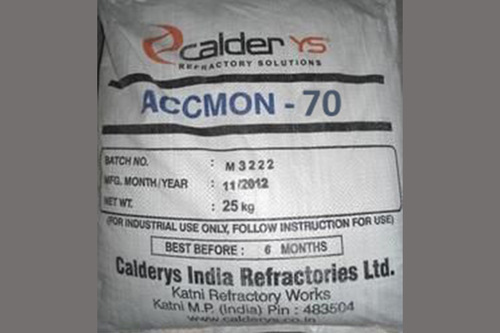

Low Cement Castables

Product Details:

- Fineness Fine

- Color Grey

- Sand Fineness Fine

- Heat of Hydration Moderate Heat

- Product Strength Grade Industrial Grade

- Feature Volume stability

- Click to view more

X

Low Cement Castables Price And Quantity

- 100 , , Kilograms

Low Cement Castables Product Specifications

- Grey

- Fine

- Volume stability

- Fine

- Moderate Heat

- Industrial Grade

Low Cement Castables Trade Information

- 5000 , , Kilograms Per Month

- 7 Days

Product Description

We offer Low Cement Castables. We offer a series of castables for different applications. These are packaged materials containing appropriately proportioned binders and graded aggregates for achieving desired properties. They will produce refractory concrete when mixed with water.

Specifications:

| Technical Specification of Low Cement Castables | |||||

| Properties | LC-45 | LC-60 | LC-70 | LC-90 | |

| Max. Service Temp.C | 1400 | 1550 | 1600 | 1750 | |

| Grading (mm) | 0-4 | 0-4 | 0-4 | 0-5 | |

| Water required in (%) | 5-6 | 6-6.3 | 5-6 | 5-6 | |

| Setting | Chemical/ Hydraulic |

Chemical/ Hydraulic |

Chemical/ Hydraulic |

Chemical/ Hydraulic |

|

| AL2O3 % > | 45 | 60 | 70 | 90 | |

| Fe2O3 % < | 1 | 1.5 | 1.5 | 1.5 | |

| CaO Max. | 2.5 | 2.5 | 2.5 | 2 | |

| B.D. gm/cc. Min Air dried 110C/24 hrs. on Vibrocast Block | 2.25 | 2.45 | 2.7 | 2.85 | |

| C.C.S. kg/cm2> | |||||

| On drying at after firing | 110C/24 hrs. 1200/3 hrs. 1400C/3 hrs. 1500C/3 hrs. |

500 | 550 | 600 | 650 |

| 650 | 600 | 600 | 800 | ||

| 1000 | 1000 | 1000 | 1000 | ||

| - | 1000 | 1000 | 1100 | ||

| at 1400C/2 hrs. | 0.3 | - | - | - | |

| at 1500C/2 hrs | - | 0.5 | +0.8 (1550C) |

+1.5 (1550C) |

|

| Application : Cooler & Discharge end of Rotary Kilns. | various | various | various | ||

| Note: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The above data relates to standard sized, machine pressed bricks only.For bigger & pneumatically rammed shapes, results may vary. General size tolerance will be 1.5 or 2mm whichever is greater. We offer Low Cement Castables. We offer a series of castables for different applications. These are packaged materials containing appropriately proportioned binders and graded aggregates for achieving desired properties. They will produce refractory concrete when mixed with water.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS